Jaci mould engineers had very rich experience and comprehensive development spirit. Their principles are: A good products' design is the key. so engineers special pay attention to the mold making; Try aborative design to play its biggest service life and reduced maintenance.

Customer provide the 2D or 3D drawings in DXF, DWG, PRT, SAT, IGES, STEP format etc, or just send us the sample. We will scan the sample and make product blueprint, begin to design the mould assembly drawing after customer's confirmation, and we customize the existing projects.

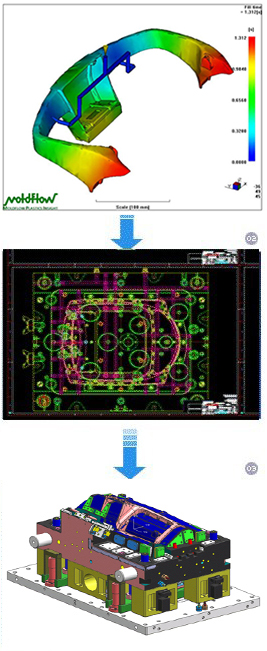

Jaci mould adopted international advanced system - CAD/CAM/CAE in mould design and injection molding.

Our engineering and mould-making technology includes:

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic flow/deform simulation)

5. MasterCAM (CNC Programming)

6. Unigraphics (CNC Programming)

7. CNC Machining Centers

8. CNC EDM's (Electro-Discharge Machining)

9. Wire-Cut Machines.

Customer provide the 2D or 3D drawings in DXF, DWG, PRT, SAT, IGES, STEP format etc, or just send us the sample. We will scan the sample and make product blueprint, begin to design the mould assembly drawing after customer's confirmation, and we customize the existing projects.

Jaci mould adopted international advanced system - CAD/CAM/CAE in mould design and injection molding.

Our engineering and mould-making technology includes:

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic flow/deform simulation)

5. MasterCAM (CNC Programming)

6. Unigraphics (CNC Programming)

7. CNC Machining Centers

8. CNC EDM's (Electro-Discharge Machining)

9. Wire-Cut Machines.

|

CAE: Our company adopt soft of MOLDFLOW to do injection simulate flow analyzing , educe the optimum project reduce the unplanned of design, greatly shorten manufacture cycle of mold design. |

| CAD 2D: We use the 2D software to design the mold such as AUTOCAD,CAXA. |

|

| CAD 3D: Our company uses 3D software to design products and separate mold structure, establish and transfer relevant accessory, form the total picture, and separate the accessory according to the conditions of machining. |